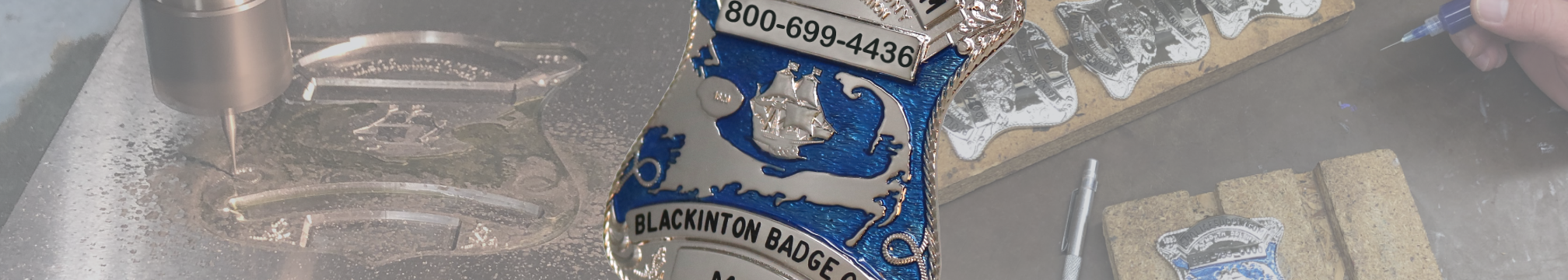

Your Badges Journey

The Road to Perfection...

The process of making a badge is very involved.

Many people ask why does it take so long to make a badge?

The reason is each badge is individually crafted and personalized for you! A major misconception is that we have your badge sitting on a shelf and when it is ordered all we need to do is engrave. To obtain the intricate detail, durability, and brilliant gleam of a Blackinton badge we start the manufacturing process from raw base metal. We encourage you to watch our video “A Badges Journey to Police Week” Click Here walks you through the manufacturing process, or if you would like to see firsthand how a badge is made give us a call and request a factory tour.

Below we have outlined some of the steps and stages involved in making your badge. To understand the choices you have when ordering a badge take a look at our badge 101 page. To get an inside look at how a badge is made click here and view our video, “How a custom badge is made.”

A Quality Focused Process

Design

A custom badges journey starts in the design stage. Our customers generally have a very clear idea of how they expect their finished badge to look. We recognize that the design of your badge is highly personal, and our artists are skilled at translating your imagination into a detailed rendering for review.

The design process can take a few days or a few weeks depending upon how many revisions the artwork takes. Our design staff works with you until the artwork meets your approval!! Once approved, the drawing becomes the primary reference used by our die cutters. We offer our design services free of charge to our customers. If your badge is one of our 1000’s of standard styles your badges journey would start at Step 3 – Stamping and Trimming.

Die Cutting and Tools

Using the approved design, a die cutter begins the work of cutting a reverse relief of the design into a softened steel block, capturing each subtle detail in the process. The art of faithfully recreating the original design in metal with such detail is what separates Blackinton® badges from ordinary badges.

Once this work is completed and the steel is hardened, the latest machines and techniques are employed to produce the trim tools, piercing tools, and making devices necessary to begin stamping your badge.

Stamping and Trimming

In the stamping process, hydraulic presses drop several tons of force onto a 4 or 5 ounce piece of raw material to “squeeze” the metal into the shape and form of the die. The metal can be “hit” with this force anywhere from three to twelve times depending upon individual design requirements.

Once all the necessary high pressure blows have been struck, each piece is carefully trimmed using automatic power presses to remove excess material. This leaves your badge with a clean, smooth edge.

Lettering and Numbering

The art of hand lettering with a hammer and steel type punches has been part of the Blackinton® manufacturing process since the beginning. This is where your badge assumes your own individual identity. Although our skilled craftsmen still use this method, called “stenciling,” for certain badges, it has been largely replaced by a computerized lettering system. This state-of-the-art method produces clean, sharp, optically balanced lettering.

Soldering

Your badge is now ready to have the necessary attachment device soldered to the back. This could be a screw back, safety catch, or even a wallet clip. On many Blackinton® badges, this is still a hand-soldering operation. More and more, however, we are using modern processes for this, including electronic fusing and conveyor ovens.

In many cases, we have found these methods to be faster, more efficient way to apply a permanent solder bond between badge and attachment.

Color

The use of color enhances the appearance of our badges, and we use three distinctly different processes to apply color. Click here to view Blackinton’s standard colors.

- The consistent, striking beauty of hard-fired enamel is created by hand using a painstaking procedure. Natural colors found in mineral substances are ground into a fine powder, moistened to proper consistency, then delicately placed by hand into each individual letter. After being fired in 1,400° ovens, the enamel is stoned flush with the surrounding metal areas. There are seventeen additional steps in the hard enamel process as compared to the other color techniques. Because of these additional steps, and the curing involved, a hard enamel badge takes 5 business days longer to manufacturer. Hard-fired enamel is standard with our high-end badges, Hi-Glo®, Rho-Glo®, Two Tone, and VHB Karat Klad.

- Epoxy is being used more and more frequently. Epoxy is a plastic material used to give an appearance similar to hard fired enamel while providing a truer color and wider variety of shades. This process is used most frequently with our seals and commendation bars.

- Painting or lettering is widely used on badges not ordered with Hard-fired enamel. This is the process used when regular enamel is ordered. This is also an individual, per piece operation. Paint is flowed into the letter then wiped out. Letters are not flush with the metal. You can feel indentation. Regular enamel is standard with nickel, rhodium, and gold plated badges.

Polishing

Your badge is nearing the end of its journey, but several important stops still remain. The high quality, smooth finish for which Blackinton® badges are noted is attained through a careful, “one-at-a-time” polishing process. Using an assortment of wheels and compounds, experienced polishers bring out the brightness and luster of the finish and remove minor imperfections in the surface of the badge. This process is accomplished one piece at a time. Polishing is one of the most important aspects of production prior to plating.

Finish Plating

Once the polishing process is completed, each badge is racked and immersed in cleansing solutions to remove all residue from previous operations. Once the badge is cleaned, any number of finishes may be applied. If your badge is made from one of our base materials; i.e., Hi-Glo or Rho-Glo they do not get finished there is a clear coating placed on the badge to enhance its durability.

Final Inspection

When your badge was designed, exacting specifications for finished appearance were prepared. After each process your badge is inspected – to ensure it meets our quality standards. Even though your badge may have gone through 5-8 inspections through its manufacturing journey we still find it extremely important to conduct a final inspection. In final inspection, we make sure that all elements of design, detail, color, and finish clearly meet those expectations. Even though each person working on your badge makes every effort to see that it meets your exact requirements, a final inspection is still made to look for the slightest manufacturing defect. If required, corrective measures could necessitate only a light polish or in rare cases, a complete remaking of the badge. We hope our customers understand that any resulting delay in delivery is caused by our commitment to quality and the very handcrafting which makes each Blackinton® badge so special.

Packing and Shipping

Our attention to quality continues through the very last step – packing and shipping. Each badge is individually poly-bagged to protect the appearance we have worked so hard to create. It is then shipped to you so that you may wear it with the same measure of pride that has gone into its skillful and careful manufacture.

We hope we’ve helped you understand the talent, time and care that is required to turn a small piece of raw material into your cherished badge.