Uncovering The Mystery Of Ordering A Blackinton Badge

The first time you order a custom law enforcement badge or fire badge it can be confusing. How can we make it simpler? First, by outlining the options you can choose. Second, and most important, outlining the manufacturing steps. In other words, if you understand what it takes to make a badge then your decisions become easier. Furthermore, timelines and budget will make more sense. Outlined below are a few things to consider when planning for your custom law enforcement badge. In addition we suggest you watch our video series “A custom badges journey to Police Week” click here to watch.

Start by contacting our Sales Group.

Why Blackinton

Experience and Capabilities

We have experience dating back to 1852, as well as a nationwide distribution network with more than 800 dealers. Because we work to bring your vision into a reality our quality custom law enforcement badges and fire badges are the best in the industry.

In addition to our experience the below attributes also set us apart from the competition.

- Made in the USA, Since 1852

- Order capacity, Namely we can handle an order of 1 badge or 1,000’s of badges

- Superior quality

- Green operations, for instance our 100% wastewater recycling, and our Solar Field

- Security

- and much much more

Badge Style

Time Line And Budget Will Guide Us

- Personalized Catalog Badge is the most economical and fastest approach. (3 weeks).

- Semi-Custom is our mid-tier option utilizing existing dies with one custom panel, or perhaps a custom seal (4-5 weeks).

- Custom is a unique design. (6-8 weeks). To start determine the graphic elements you would like included in the design of your custom law enforcement badge or fire badge (building, patch, landmark, etc). Then our designers turn your ideas into artwork, and eventually a custom badge.

Pricing and Budget

What Effects The Cost Of A Badge?

- Badge Finish

- Applied Seals are graphical metal emblems applied to the center of a badge.

- Quantity Discounts We offer quantity discounts for the same style badges if they are ordered on the same PO#. You can mix finishes, titles, and numbers only – not names.

- 1-12 Badges = Net – 13-24 Badges = 5%

- 25-49 Badges = 10% – 50-99 Badges = 15%

- >100 = 20%

Enamel

Vibrant Colors Enhance A Badges Beauty

- Plain is typically a badge with raised lettering or no lettering. As a result the manufacturing process is faster because it skips the enamel process.

- Regular Enamel

- Paint is flowed into letters, and the letters are not flush with metal.

- This is our standard enamel for our lower end finishes like; Nickel, Rhodium, and gold plated badges

- Dura / Hard Enamel

- Color is flowed into the letters, and then a 1500 degree oven fires the badge. After the oven excess enamel is stoned down until the letters are flush with the metal. This enamel is like hard fired glass.

- Because there are 17 extra manufacturing steps, add five business days to manufacturing the badge.

- This is our standard enamel for our high-end badge like; Hi-Glo, Rho-Glo, Two-Tone, and VHB KK

- If you request hard enamel on a lower end finish there is a small add on cost.

- Standard Colors for lettering are Blue, Black, Red, Green, Brown, and White lettering.

Badge Back Options

Solid Back Badge is a heavier badge because we press more metal. Resulting in a more durable non-snagging finish. Because the back of the badge is smooth we recommend solid back if you plan to engrave the back of the badge.

The majority or our standard law enforcement and fire badges come with a shell back. After we manufacture a badge the back can not be changed.

Understanding Panels

What is a panel? The area on a badge that takes or has lettering for instance rank, department, city, state, name, etc. Additionally a panel can have lettering in the die or engraved.

- One Piece Badge the badge is made from one piece of base metal and the panels are in the die.

- Applied Panel Badge assembled using different panels (pieces). Below is an example of a panel badge.

What type of panel would you like?

- Incised panel has the lettering in the die or it can be engraved. Additionally, incised panels have color inside the letters.

- Reversed panel is when color is flowed into the panel, and the letters are the color of the metal. Consequently lettering in always in the die of a reverse panel.

Engraving and Text Separators

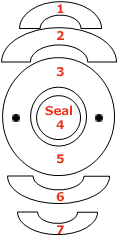

Lettering personalizes your badge. In fact there can be up to 7 lines of lettering on a badge. Additionally, count panels out starting from the seal which is line 4 (see below).

Also, A circular panel can have text separators, see the below outline. For example either a circle or star.